Precision Semi-Automatic Universal Cylindrical Grinder

Tel:

Precision Semi-Automatic Universal Cylindrical Grinder

Machine Features:

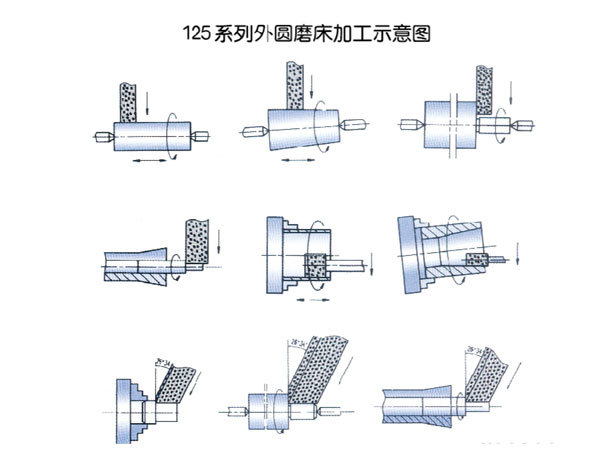

★This machine tool is suitable for precision grinding of outer cylindrical surface, outer conical surface, inner hole and inner conical surface of workpiece.

★The grinding wheel frame, head frame and worktable of the machine tool can be rotated at a certain angle, and the worktable and grinding wheel frame can be manually driven in addition to hydraulic drive. to fit

Workshop or machine repair

★This machine tool can be processed by means of top, chuck or spring chuck, to meet the needs of precision couplers, measuring tool production workshops, tooling and moulding workshops, and machine repair workshops

TECHNICAL SPECIFICATIONS

Height of center 100mm

Distance between centers 270 /520mm

Diameter to be ground φ5-φ125mm

Max. length to be ground 250 /500 mm

Aperture to be ground φ10-φ40

Max. depth to be ground 50 mm

Table rotation angle ± 9°/± 7°

Rotation angle of headstock ± 45°

Rotation angle of grinding wheel rack ± 180°

Max. weigth of workpiece 10kg

Dimensionof Max. grinding wheel φ300×(20-40)×φ127mm

Linear speed of grinding wheel ≤35m/s

Motor power of grinding wheel rack 2.2kw

Outline dimension of machine tool

1550×1190×1600/2240×1190×1600mm

Net weight

1800/ 2100 Kg

Gross weight 1900/2200 Kg

WORKING ACCURACY(Grinding national standard test parts)

Roundness:Top grinding outer circle 0.001 mm

Chuck grinding 0.003 mm

Chuck grinding inner circle 0.002 mm

Cylindricity: 0.003 mm

Surface roughness: top grinding outer circle Ra: 0.04μm

Chuck grinding Ra: 0.08μm

Chuck grinding inner circle Ra: 0.02μm

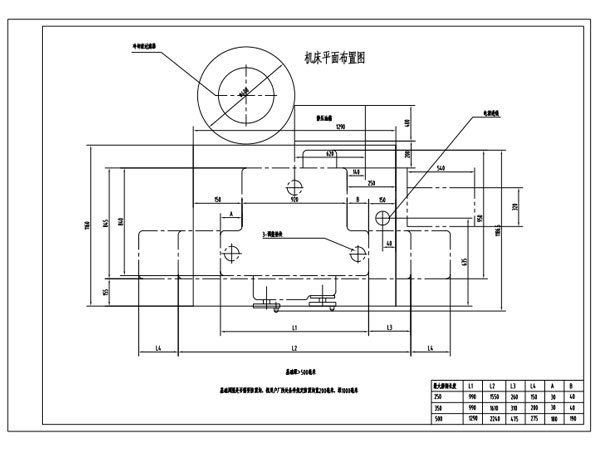

Layout plan

1. Host height 1300mm

2. The machine tool should be installed on a solid foundation away from the vibration source, and the installation level should be adjusted with the 3 pads under the machine tool. Check the levelness of the machine with a spirit level. Vertical ≤0.04/1000, horizontal ≤0.04/1000, when the machine tool is adjusted, the necessary auxiliary pads can be added, and concrete can be injected to fix it

ONLINE MESSAGE

RELATED PRODUCTS

CONTACT US

Add : No. 2126, Kejia Road, High-tech Zone, Jinan City

Copyright© 2022 : Jinan Siji CNC Machine Tool Co., Ltd. 鲁ICP备09070256号 Powerby : 300.cn jinan SEO

+86-0531-88681424

+86-0531-88681424

sale@j4m.cn

sale@j4m.cn