CNC crankshaft special grinder

Tel:

CNC crankshaft special grinder

Machine Features:

★The machine tool adopts five-axis numerical control system, built-in PLC, and 10.4-inch color liquid crystal display. The operator can set the grinding parameters in the man-machine conversation mode through the display screen, edit the grinding process cycle, and realize the automatic grinding of the machine tool.

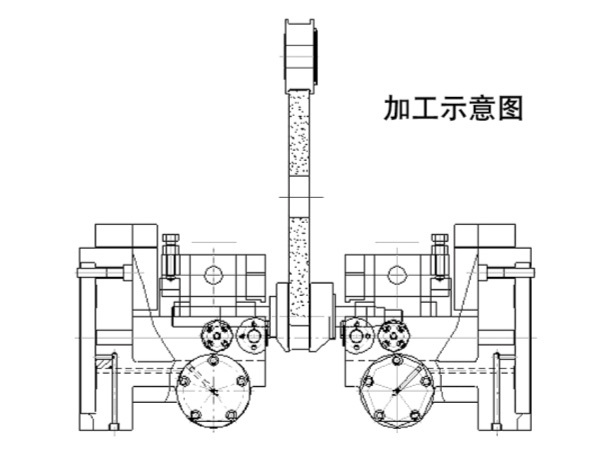

★Using a double-head frame to drive two sets of special eccentric V-shaped fixtures through two AC servo motors (C1, C2) to achieve synchronous rotation and machining of eccentric outer circles. Rigid positioning is adopted for the rotation of the headstock when loading and unloading workpieces.

★The workpiece corner is automatically positioned by the workpiece grinding outer circle; hydraulic automatic clamping.

★Use the rear diamond roller to dress the grinding wheel. The grinding wheel frame feed X1 axis and the diamond roller dressing feed X2 axis are respectively completed by the AC servo motor driving the ball screw, which makes the grinding wheel dressing and compensation more reliable.

★The machine tool is equipped with an outer circle active measuring instrument and an end face positioning device to realize axial positioning and closed-loop control of outer diameter grinding;

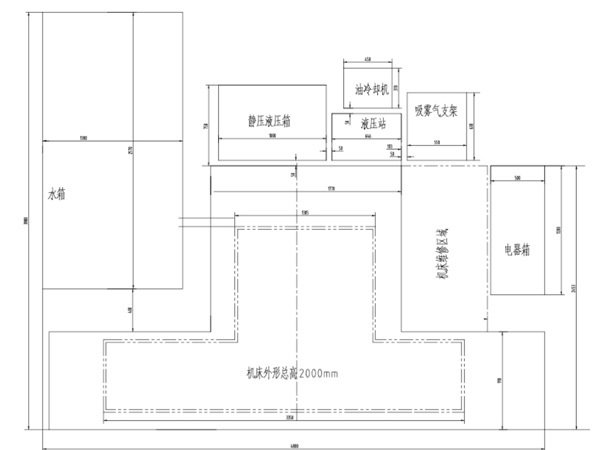

★The grinding wheel spindle adopts the German technology integral dynamic and static pressure bearing structure, which has high rotation precision and high rigidity; the independent static pressure oil tank uses No. 2 spindle oil and is equipped with a pressure gauge display.

★The headstock spindle of the machine tool adopts the precision rolling bearing structure and selects P4 grade bearings; adopts the AC servo spindle motor to realize the synchronous stepless speed change of the two axes, and has the function of accurate stop

★The machine tool adopts an integral casting high rigidity bed and a full protective cover (the upper part is open), and the glass window of the front door is protected by iron mesh and protective door lock. The four boxes of the machine tool (hydraulic oil tank, dynamic and static pressure oil tank, water tank, electrical box) are independent, which is convenient for operation and maintenance.

TECHNICAL SPECIFICATIONS

Max. rolling diameter 350mm

Max. length to be Installation 600mm

Max. length to be ground 300mm

Max. weigth of workpiece 50kg

Linear speed of grinding wheel 50m/s

Dimension of Max. grinding wheel φ750×φ203×Bmm

Resolution of axis X、Z 0.0001mm

Power of the grinding wheel motor 11kw

Total power of the motors 30kw

WORKING ACCURACY(Grinding national standard test parts)

Roundness 0.003 mm

Cylindricity 0.005 mm

Surface roughness Ra0.4μm

Parallelism 0.01

ONLINE MESSAGE

RELATED PRODUCTS

CONTACT US

Add : No. 2126, Kejia Road, High-tech Zone, Jinan City

Copyright© 2022 : Jinan Siji CNC Machine Tool Co., Ltd. 鲁ICP备09070256号 Powerby : 300.cn jinan SEO

+86-0531-88681424

+86-0531-88681424

sale@j4m.cn

sale@j4m.cn